- sales@hebeimaoheng.com

- 0086-18833173186

Factory Cheap Hot Modern Processing Machine – Hemp Seed cleaning Machine(5XFZ-15STM) – Maoheng

Factory Cheap Hot Modern Processing Machine – Hemp Seed cleaning Machine(5XFZ-15STM) – Maoheng Detail:

Maoheng Machinery-Grain Processing Machine

→Product Description:

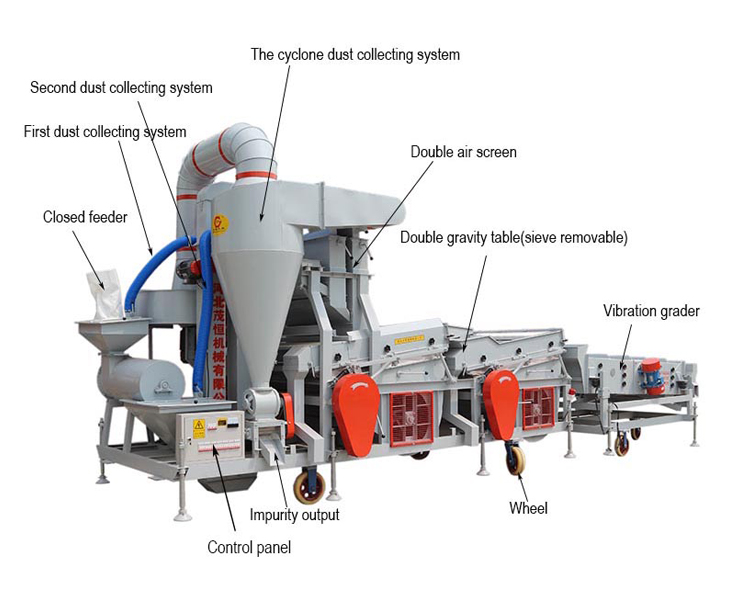

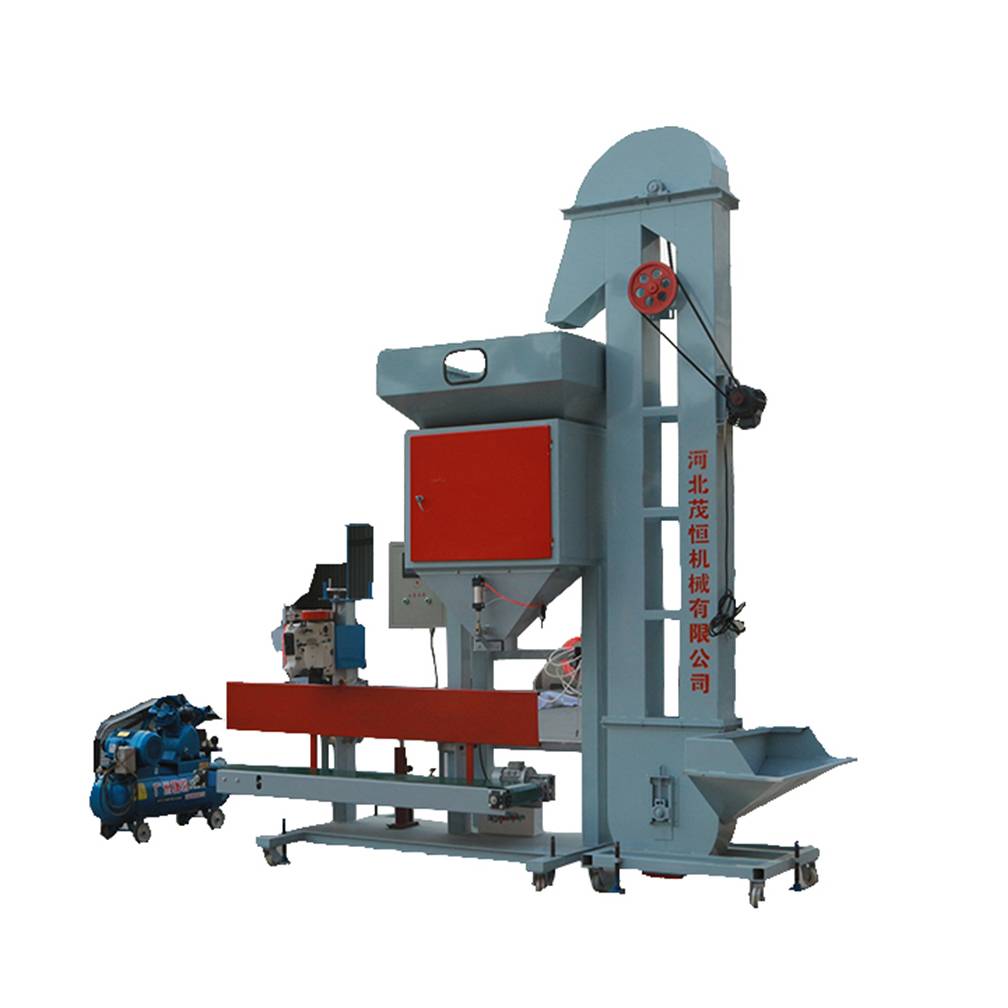

The 5XFZ-15STM Grain Air-cleaning Machine consists of wheat sheller, air-screen system,dust removal system,

gravity table,sizing machine,no crushing lifting,etc.

→Specification:

| Model | Size | Weight | Power | Capacity | Sieve size | Gravity Table Size |

| 5XFZ-15SM | 8.0*2.5*3.18M | 4.0T | 28.5Kw | 10 TPH | 2.4*1.5M | 1.8*1.6M |

| 5XFZ-15STM | 8.5*2.5*3.18M | 4.2T | 36Kw | 10TPH | 2.4*1.5M | 1.8*1.6M |

→Multi-angle display:

→Features:

1.The dehuller and elevator are equipped with a dust removal system, and the operation is more environmentally and friendly, and the whole process is closed;

2.The thickeness of the delluer housing is 8mm, more wear-resistant make the machine long life span,

3.Non-broken elevator(The material does not break during the lifting process)

4.Double vertical air screen with double lateral cyclone dust remover

(reasonable adjustment of air volume )

5.the cyclone dust collecting system(800 mm diameter dust removal effect is better to effectively improve the working environment)

6.It’s convenient to change the different type of the gravity table sieves for different grain.

7.Double gravity table can make the cleaning precision up to 98%, The size of the vibrating sieve is1.5m by 2.4m( vibrating screen lengthened sorting effect is more thorough small particles, broken particles sieve in addition to more thoroughly);

8.According to the quality of the grain need to be processed, You can makethe plan for the process one gravity table or two gravity table freely. In order to achieve the purpose of cleaning.(reducing electricity consumption by 9KW per hour);

9.The gravity table is removable, it is easy to clean the sieves(It will not affect the specific gravity separation effect because of the blockage of the specific gravity table, at the same time, according to the different materials to choose the use of different specifications of the specific gravity table, truly multi-purpose one machine);

10.Electronic control system upgrade, greatly reduce the probability of burning motor;

11.All cables are equipped with conduits for safer electricity use.

The structure of the whole machine is compact and easy to move. This machine is the most advanced processing equipment among the current seed processing and grain processing equipment. Double air selection and double proportion – it is the trend of seed processing enterprises to upgrade their products – double air selection and double proportion: only In order to remove impurities and achieve reasonable control – double air selection and double proportion: only for impurities removal and can achieve reasonable control.

Simple operation, low failure rate, large output, good effect, and wide adaptability (maize, wheat, rice, sorghum and other crops can be used)!

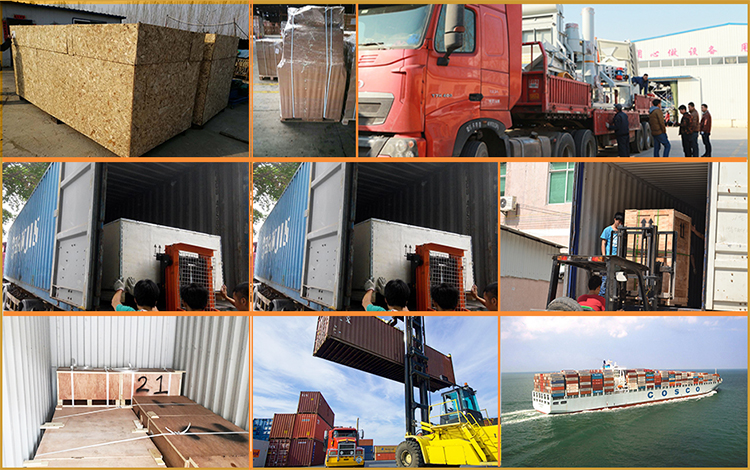

→Transport and packaging:

Product detail pictures:

Related Product Guide:

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for Factory Cheap Hot Modern Processing Machine – Hemp Seed cleaning Machine(5XFZ-15STM) – Maoheng , The product will supply to all over the world, such as: Tunisia, Morocco, New York, We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our products. Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us.

1.Q:What is the seed/grain cleaning?

A:This is the process of removing low quality, shriveled, mouldy seeds and different crop varieties from seeds or grains. Seed cleaning includes dust removal,specific gravity, grading, polishing, stone removal, color sorting, coating, packaging and weighing. Seed cleaning is a part of the seed industry, responsible for upgrading seeds and improving their planting conditions. This helps to improve the quality of the seeds, thus ensuring increased farm productivity.

2.Q: Are you factory or trading company?

A :We are professional manufacturer for grain cleaning equipment and we have 19 years of production and sales experience in the industry.

3.Q: What do you need to know for fast communication and quotation?

A: It would be highly appreciated if you can provide details of your processing material spics, capacity and efficiency request, sieve specification, motor power supply voltage and special brand needed, and other working conditions.

4.Q:Can One Machines work on different seeds?

A:We also use individualized, seed specific settings on our machines to limit unwanted scarification. We provide number screens to be fitted on single machinery to our work on different variety of seeds.

5.Q: How long will the products be shipped to me?

A:About 10 to 40 days by sea,depend on which country you are in and the type of machine and parts availability.

6.Q: What is your payment terms?

A: T/T, L/C, Western Union, Cash accepted.

30% deposit with purchase order, 70% balance paid before shipment.

7.Q: Can you make the machines as per our special requirement?

A: Yes, OEM/ODM service available.

8.Q: Where is your factory and how can I visit?

A:The factory address:CN,Hebei,shijiazhuang,South of Nanxicun Village,ETDZ:

From Guangzhou Baiyun international airport to Shijiazhuang international airport need about 3hours then drive to my factory(1hour)

From Beijing Railway station to Shijiazhuang Railway station need about 2 hours,then drive to the factory (30 minutes)

From Hongkong International airport to Shijiazhuang international airport need about 5 hours,then drive to the factory(1 hour).

Q: What is your company after-sales service?

A: Everey machine enjoy one year warranty. We will offer fully guidance on operation questions.And engineer online service available. Any parts problem happended during the warranty year, our company will offer you spares. After warranty, we help clients solve problem patiently as our repsonsibility.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.