- sales@hebeimaoheng.com

- 0086-18833173186

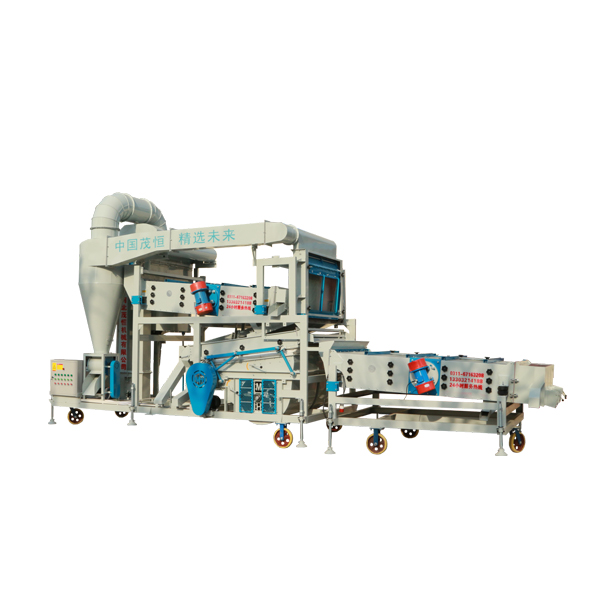

Professional China Rice Processing Machine - Multi-function Sorting & Processing Machine – Maoheng

Professional China Rice Processing Machine - Multi-function Sorting & Processing Machine – Maoheng Detail:

→Description:

The machine runs smoothly, has a compact structure, low failure rate, large output, good effect, easy operation, excellent operating environment, no breakage during processing, and can be widely used in the selective processing of various crop seeds and grains (corn, wheat, etc.), sorghum, soybean, rice, millet, rapeseed, quinoa, Gorgon, barley, etc. and various flower seeds).

By rationally distributing the air volume of the two vertical air screens, using the suspension principle of the material, combined with two lateral vortexes to remove light impurities, so that there is no valuable grain in the light impurities, and the chaff and dust in the material are removed. , glume shell and other light impurities are completely removed.

By reasonably adjusting the specific gravity typhoon volume and the height of the baffle plate of the specific gravity table, and using the principle of material density segregation, the specific gravity table can completely remove the scum, diseased seeds, mildew, and immature grains in the material.

The large and small impurities can be removed by the vibrating grader, and the selected materials can be divided into three varieties: large, medium and small, and discharged from different outlets. The sorting principle of the vibrating screen is determined according to the geometric size characteristics of the material. The types and varieties of grains are different, and the sizes are also different. Choosing to replace the screens of different specifications can meet the sorting requirements.

→Specification:

| Model | 5XFZ-40TM | 5XFZ-40BSTM | 5XFZ-40STM | 5XFZ-40BXM |

| Size(Cm)(Length*Width*High) | 500*250*390 | 730*250*390 | 1004*250*390 | 820*250*390 |

| Power(Kw) | 30.5 | 39.5 | 40.6 | 24.1 |

| Voltage | 380V 50Hz | 380V 50Hz | 380V 50Hz | 380V 50Hz |

| Weight(Kg) | 4040 | 5090 | 5790 | 4800 |

| Capacity(Kg/h) | 15000 | 15000-20000 | 15000-20000 | 15000-20000 |

| Grader sieve(Cm) | 150*240*3 layers | 150*240*3 layers | 150*240*3 layers | 150*240*3 layers |

| Gravity table(Cm) | 190*195 | 190*195 | 190*195 | 190*195 |

| Selected rate | ≥99.5% | ≥99.5% | ≥99.5% | ≥99.5% |

| Breakage Rate | ≤0.2% | ≤0.2% | ≤0.2% | ≤0.2% |

| Noise | ≤70DB | ≤70DB | ≤70DB | ≤70DB |

| Dust collector diameter(mm) | 800 | 800 | 800 | 800 |

| Cleaning precision | ≥99.5% | ≥99.5% | ≥99.5% | ≥99.5% |

| Production requirements | Whole spraying process | Whole spraying process | Whole spraying process | Whole spraying process |

| Note | With “soft”starting system | Equipped with wheat sheller | The specific gravity table can be pulled out and cleaned |

→Multi-angle display:

→Features:

1. The nin-broken bucket elevator configuration is 15 tons;

2. Dust collector 800 mm diameter;

3. Front and rear double vertical air screen;

4. The upper vibrating screen is 1.5 meters wide and 2.4 meters length;

5. The specific gravity table is 1.95 meters wide and 1.9 meters length;

6. The bottom vibrating screen is 1.5 meters wide and 2.4 meters length;

7. The specific gravity table can be pulled out, and it is more convenient to clean and replace the varieties;

8. Modular composition design, easy to move, simple to operate, all technical parameters of this equipment are well-known, and have their own characteristics, easy to use, practical and durable;

9. Advanced electronic control system (safer electricity usage)

Product detail pictures:

Related Product Guide:

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for Professional China Rice Processing Machine - Multi-function Sorting & Processing Machine – Maoheng , The product will supply to all over the world, such as: St. Petersburg, Swedish, Serbia, Ought to any of these products be of curiosity to you, remember to allow us to know. We are going to be satisfied to give you a quotation on receipt of one's in depth specs. We've our private experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

1.Q:What is the seed/grain cleaning?

A:This is the process of removing low quality, shriveled, mouldy seeds and different crop varieties from seeds or grains. Seed cleaning includes dust removal,specific gravity, grading, polishing, stone removal, color sorting, coating, packaging and weighing. Seed cleaning is a part of the seed industry, responsible for upgrading seeds and improving their planting conditions. This helps to improve the quality of the seeds, thus ensuring increased farm productivity.

2.Q: Are you factory or trading company?

A :We are professional manufacturer for grain cleaning equipment and we have 19 years of production and sales experience in the industry.

3.Q: What do you need to know for fast communication and quotation?

A: It would be highly appreciated if you can provide details of your processing material spics, capacity and efficiency request, sieve specification, motor power supply voltage and special brand needed, and other working conditions.

4.Q:Can One Machines work on different seeds?

A:We also use individualized, seed specific settings on our machines to limit unwanted scarification. We provide number screens to be fitted on single machinery to our work on different variety of seeds.

5.Q: How long will the products be shipped to me?

A:About 10 to 40 days by sea,depend on which country you are in and the type of machine and parts availability.

6.Q: What is your payment terms?

A: T/T, L/C, Western Union, Cash accepted.

30% deposit with purchase order, 70% balance paid before shipment.

7.Q: Can you make the machines as per our special requirement?

A: Yes, OEM/ODM service available.

8.Q: Where is your factory and how can I visit?

A:The factory address:CN,Hebei,shijiazhuang,South of Nanxicun Village,ETDZ:

From Guangzhou Baiyun international airport to Shijiazhuang international airport need about 3hours then drive to my factory(1hour)

From Beijing Railway station to Shijiazhuang Railway station need about 2 hours,then drive to the factory (30 minutes)

From Hongkong International airport to Shijiazhuang international airport need about 5 hours,then drive to the factory(1 hour).

Q: What is your company after-sales service?

A: Everey machine enjoy one year warranty. We will offer fully guidance on operation questions.And engineer online service available. Any parts problem happended during the warranty year, our company will offer you spares. After warranty, we help clients solve problem patiently as our repsonsibility.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.